Product Development & Testing: Oxygen Concentrator

Scroll ↓

-

March 2024 - November 2024

-

Medical Eng. Student, Med/Mech Eng. Student, Supervising Professor

-

Product Development & Prototyping

-

End-user product design

Pilot prototype design and assembly

Experimentation support

Comparative analysis of experimental and simulation data

Design review

Project delivery report

-

Queensland University of Technology — Honours Project

Our main consideration in this project is delivering accessible and consistent oxygen to children in low-resource settings in the South Pacific, where people don’t have access to a hospital and are limited by their infrastructure. This is achievable with a device design following these criteria:

Replaceable parts which are widely available in the region of application, allowing it to be maintained with accessible tools

Simplicity of design for production and manufacturing, influencing cost-effectiveness

Power adaptability for viable application in these nations

Device reliability given environmental conditions

Understanding the problem

Respiratory conditions are a priority issue in low-to-middle income countries (LMIC’s). Focusing on children, Pneumonia accounted for 14% of all deaths of children younger than 5 years old, as found in a WHO study conducted in 2019. Two significant challenges identified were that components in oxygen concentrators aren’t easily replaceable and devices are insufficient for their demographic, including excessive power requirements.

Establishing design principles

Developing countries are missing a portable oxygen concentrator device with open-source accessibility and low power demands. After researching available literature, we found the Propagating Pulse Adsorption (PPA) method ideal for “bulk air”, sacrificing high oxygen purities >80%, which are not required to save the majority of children with pneumonia. To evaluate this method, assumptions are required for specific controls and inputs to enable the selection and synthesis of components within the pilot prototype. Oxygen concentrator technical guidelines will support these assumptions, providing information on patient requirements and environmental operating conditions to influence component and material selections.

Input ranges for key components in testing

Problem definition

The high-level problem we initially focused on was, “A way to deliver a consistent supply of concentrated oxygen to improve the quality of life for children in the South Pacific with pneumonia and without access to a hospital”. This led to our aim; produce purified air at high flow rates with the intention to meet basic human oxygen requirements rather than international medical grade performance standards.

Pilot prototype design

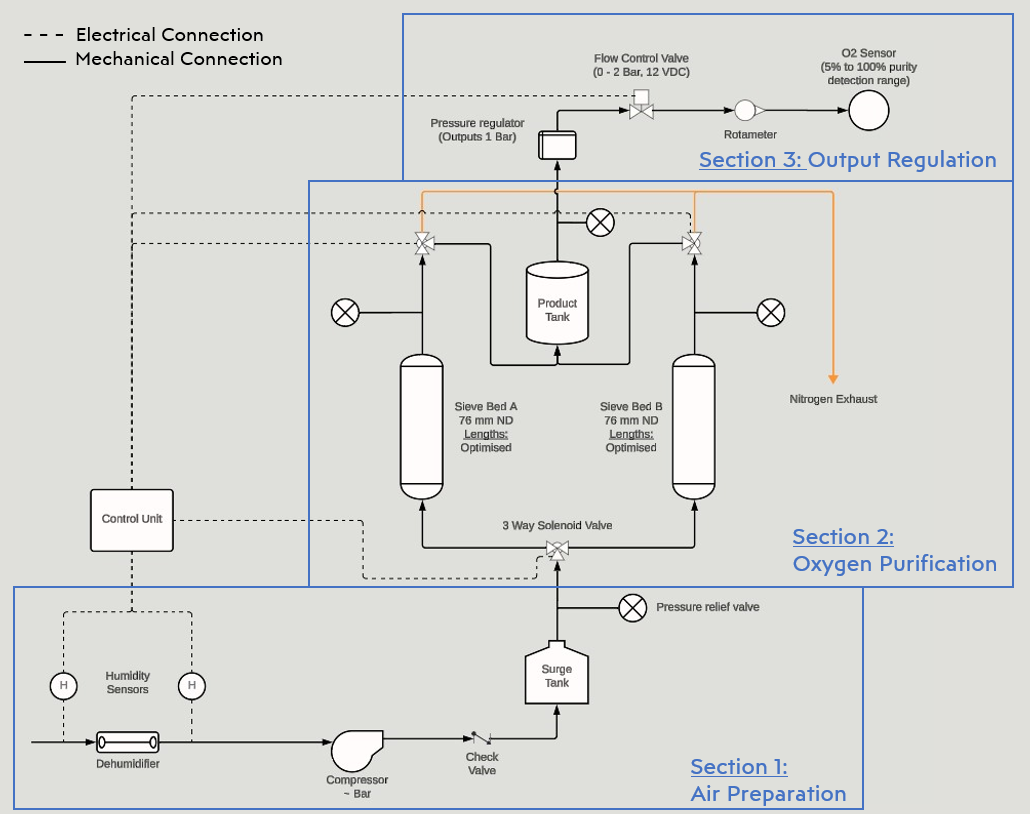

Following the project’s design criteria and established design principles outlined earlier, we designed the following multi-bed model to achieve our aim.

Multi-bed model outlining internal system of our Minimum Viable Product (MVP) design

However, for the purpose of building a pilot prototype to evaluate whether the novel PPA method is feasible and to optimise the pulse flow performance, only the necessary components of the MVP design will be required. This led to the simplified single-bed model designed for experimentation balancing a level of complexity to ensure it can be built and tested within our timeframe, and the performance data gathered applies to the behaviour of a real system.

Tests viability of PPA novel approach —> Reduce to one sieve bed

Robust Labratory equipment —> Remove unnecessary end user and device safety components

Single-bed model outlining internal system of our experimental design

While the single-bed model is constructed for parameter testing and feasibility confirmation. The multi-bed model is an important initial design as it:

Creates a foundation for component selection and system design

Provides a refined understanding of an oxygen concentrator device

Can be used to simulate full-system functionality after parameter optimization

Prototype build

For experimentation, a simple frame was constructed to imitate the structure and orientation of a true oxygen concentrator device. But the two most technical components were the sieve bed, which required the zeolite (a non-porrous material that absorbs nitrogen) to be packed tightly, and the control unit, used to open and close the valves directing air flow. A layout of the control unit I constructed is detailed below, allowing for it to be re-used in the multi-bed model, should another group continue our project.

Control unit assembly

Detailed control unit assembly parts

Testing and Simulation

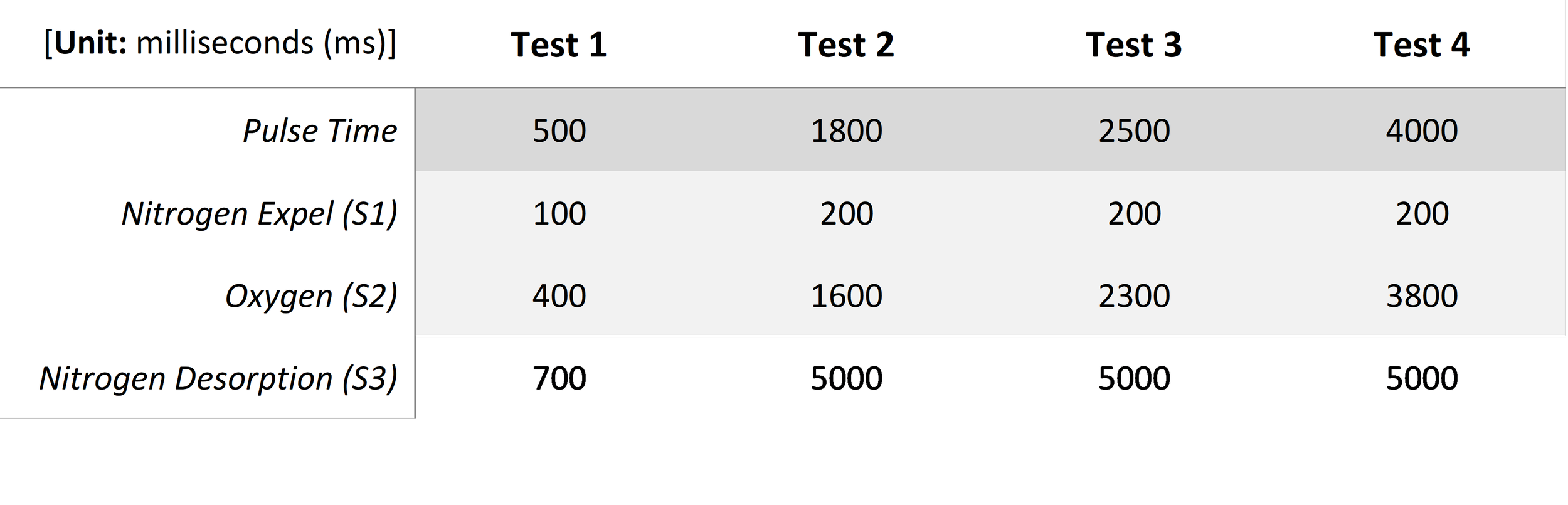

Three key parameters were identified, including pressure, bed size, and pulse timing, which would become our independent variables, tested to identify optimal conditions for maximum output oxygen purity, our dependent variable. Multiple tests were constructed, isolating one independent variable at a time to pinpoint each parameter’s optimal range. Conducted in a laboratory environment, these tests were replicated in COMSOL, a multiphysics simulation software, which we used to validate experimental results.

To help you understand these tests, the model is coloured to illustrate the flow of air in three stages, representing the reset (S3), the pulse (S2), and the purge (S1).

S1

S2

S3

Three respective stages of a pulse (green is open & red is closed)

Results

Four tests were conducted to assess pulse timings independently, as different-sized beds were hypothesised to have different optimal operating conditions, which was confirmed. Smaller beds were more effective with shorter pulses, and longer beds with longer pulses, with the longest bed and the pulse timing from test 4 outperforming the rest.

Pulse timings for tests 1 to 4

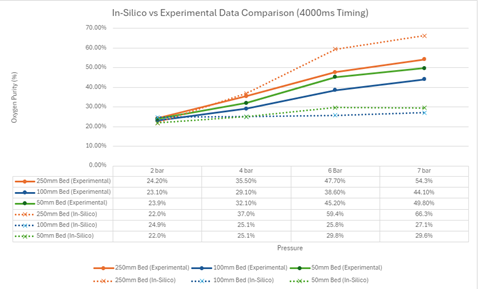

As presented in the results below, the aforementioned is proven with the 250mm bed outperforming the rest in both the experimental and simulation (In-Silico) results, when using the pulse timings from test 4. However, there was concern with the reliability of the experimental data as the distinction between the 250mm bed and the rest should have been greater, as represented by the simulation results.

Experimental vs computational results for test 4 (apologies for the poor quality)

Simulation data was able to express realistic zeolite behaviour characteristics, with the short beds saturating quickly with the long pulse, and the long bed performing optimally.

The proposed “bulk air” approach has the potential to fulfill the end users’ requirements, as the device was able to concentrate oxygen within this 40% to 60% range for multiple cases. This oxygen purity range was achieved with a pressure of 5-7 Bar, which can be produced by compressors with low power consumption, ideal for our end user. Both test methods supported this, specifically the simulation results, but the experimental data was deemed inconclusive due to the lack of reliable correlation.

There are three likely reasons for the experiment’s skewed results, including the pressure-dependent oxygen sensor, negligence of pipe diameters and flow resistances, and the zeolite leak in the 100mm bed, as a mesh grate became loose inside the bed. While the second reason was human error, attempts were made to reduce pressure dependency for the oxygen sensor, thus improving redundancy, by adding pressure regulators and relief valves, but they proved ineffective. While it isn’t certain that the output was effected by pressure, given the system was open to ambient air, the data was unable to be verified and validated.

Future Improvements

Include grooves in the PVC piping to secure mesh grates

Use vibration tooling to pack the zeolite tighter in the beds

Secure an oxygen sensor that measures the concentration of oxygen molecules in the gas as a percentage, a value that is independent of pressure

Include a flow meter on the output as a comparative parameter to validate the test

Even though the models aren’t validated, the simulation and experimental results still have suitable reliability and present notable findings for further examination. The “bulk air” approach does concentrate oxygen.